subNav_3Tier

Bridge MULTICOM Girder Overview and Features

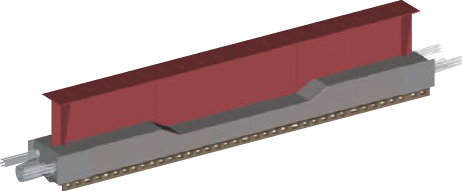

Complete Composite

Action of

Concrete Panel and I-Girder Achieved!

By combining concrete panels with I-girders, issues such as cracks and height differences due to thermal expansion and contraction of the steel during temperature changes before and during the non-shrink concrete pour are completely resolved. This eliminates quality issues caused by differential deflection between the panel and the girder.

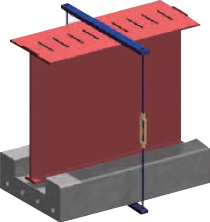

Problems with Conventional Methods

When the I-girder is manufactured with greater camber than the concrete panel

The girder’s mid-span height becomes greater than at both ends.

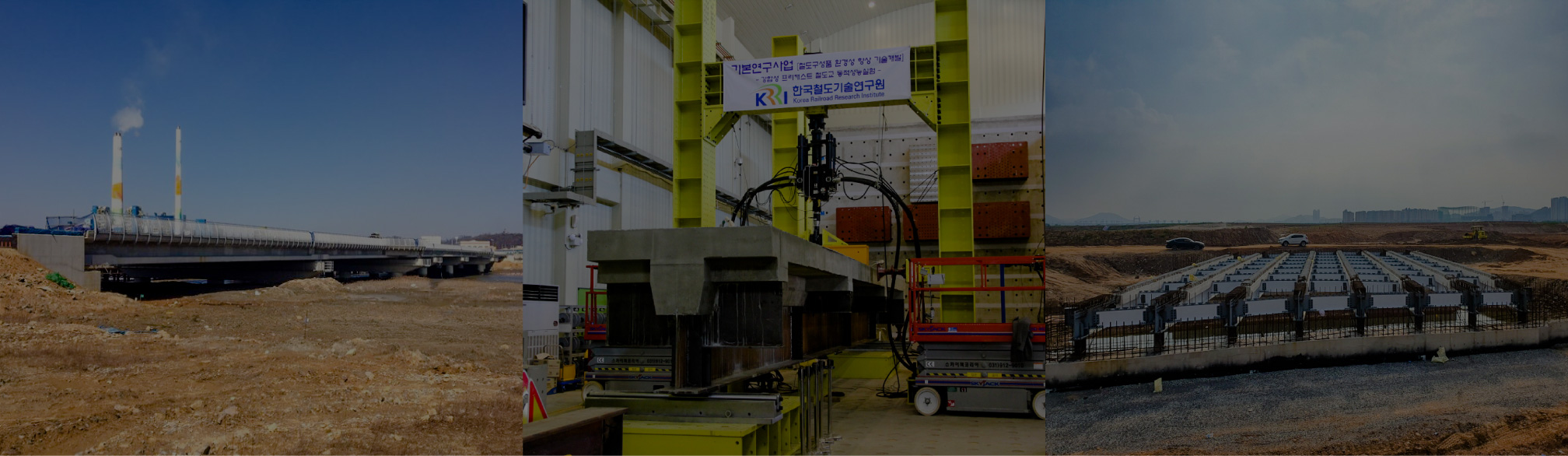

Excellent Constructability,

Outstanding Cost-Effectiveness,

Revolutionary Structural Performance

- Eliminates all high-altitude work, ensuring superior safety

- Simplified full construction process enables easy installation

- Low neutral axis prevents overturning during erection

- Reduces steel usage by 30–50% compared to conventional steel composite girders

- Minimizes land lease area for manufacturing yards

- Short construction cycle reduces overall cost

- Enables concrete crack control by compensating for stress loss during manufacturing stages

- No cracks occur thanks to full prestressing method

- Achieves full composite action between precast panel and steel using T/B connection device

Maintenance Cost Reduction via Re-Prestressing

Efficient maintenance using unbonded PC strands

[ Re-tensioning possible during service life, excellent durability and appearance ]