subNav_3Tier

Bridge DS Steel Composite Girder Comparison with Similar Methods

Category

DS Steel Composite Girder /

Rigid Frame Bridge

Preflex Composite Rigid Frame ①

Preflex Composite Rigid Frame ②

Method Overview

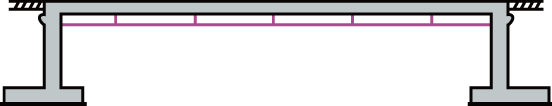

A composite frame method using DS composite girders placed on adjustable connection bearings at the top of the abutment. The system behaves as a simply supported structure under pre-composite dead loads, and transforms into a rigid frame structure under post-composite dead and live loads.

A composite rigid frame method using preflex composite girders. Simply supported under self-weight and pre-composite dead loads with round bearings that allow rotation/movement, and behaves as a rigid frame under post-composite dead and live loads.

A method where preflex composite girders are inserted into L- or T-shaped steel structures atop pre-constructed wall elements, connected using high-strength bolts. The upper structure, remaining walls, and columns are cast to form an integrated rigid frame.

Structural System

Girder Type

DS Girder

Tensioning

Post-tension

Self-weight

Simply Supported

Before Composite

Simply Supported

After Composite

Rigid Frame

Girder Type

Preflex Girder

Tensioning

Pre-tension

Self-weight

Simply Supported

Before Composite

Simply Supported

After Composite

Rigid Frame

Girder Type

Preflex Girder

Tensioning

Pre-tension

Self-weight

Simply Supported

Before Composite

Simply Supported

After Composite

Rigid Frame

Features

- Full prestressing ensures excellent crack resistance due to DS girder structural characteristics

- Time-dependent compression loss is compensated by staged tensioning, allowing precise design and construction

- Simple fabrication process enables shorter construction period

- Partial prestressing results in reduced crack resistance due to preflex girder structure

- Requires highly precise fabrication due to preflexing and release stages

- Tensioning of positive/negative moment members must be done mid-air, increasing complexity and construction time

- Partial prestressing results in reduced crack resistance due to preflex girder structure

- Factory fabrication enables easy quality control and construction management

- Requires highly precise fabrication due to preflexing and release stages

Cost Efficiency

(Based on 30m)

100% (KRW 1,500,000/㎡)

146% (KRW 2,200,000/㎡)

150% (KRW 2,250,000/㎡)

Girder Height and Construction Cost of Rigid Frame Bridge

- DB-24DL-24

- B = 20.0m (8 girders)

- 90° square-type direct foundation

- Earthwork excluded

- Labor rate applied to material costs

Span (m)

20

25

30

Remarks

Girder Height

(incl. slab thickness)

0.9m

1.0m

1.2m

Unit Girder Cost

(KRW million)

3.542

4.427

5.313

Girder Cost per ㎡

(KRW thousand)

45

56

67

Slab & Lower Structure Cost

per ㎡

93

82

70

Direct Construction Cost

per ㎡

128

118

117

Total Construction Cost per ㎡

(incl. 40% overhead)

165

150

150

※ Girder cost includes both upper and lower connection structures.