subNav_3Tier

Bridge MULTICOM Girder Standard Unit Cost

(Based on 2014 Road Bridge Standards)

Category

R.P.F

E-BEAM

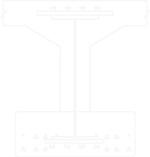

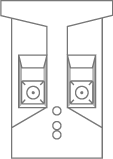

Girder Cross Section

1. Steel girder fabrication

2. Placement on bed

3. Preflexion

4. Reinforcement & concrete casting

5. Steam curing

6. Release

7. Strand tensioning

8. Girder erection

9. Deck slab casting

1. Bed preparation & production

2. Reinforcement & casting

3. Steam curing

4. 1st strand tensioning

5. Girder erection

6. Deck slab casting

7. 2nd strand tensioning

Materials Used

■ Steel: SM490–520

■ Concrete:

- Slab, upper: 27MPa

- Lower casing: 45~48MPa

■ PC Strand:

- SWPC 7B 15.2, Fpy = 190MPa

■ Steel: SM490

■ Concrete:

- Slab, upper: 27MPa

- Lower casing: 40MPa

■ PC Strand:

- Unbonded, mono 15.2, Fpy = 190MPa

Method Overview

A composite method using approx. 80% of the Preflexion load compared to the traditional method to induce elastic recovery in the steel I-girder and introduce initial prestress to the lower flange concrete. Additional prestress is applied using unbonded strands.

A method that enhances eccentric efficiency by integrating steel plates on the upper flange, reducing girder height. Prestress is applied at different construction stages by unifying the continuity point with steel plates + rebar + prestressing material.

Advantages & Disadvantages

- Long-term storage after compressive prestress in the lower flange may cause excessive prestress loss

- Full prestressing design ensures high crack resistance

- Wide flange makes it less suitable for curved bridges compared to PSC beams

- Full prestressing design ensures high crack resistance

Cost-Effectiveness

(35M)

High steel consumption and separate 7-day concrete curing for compressive prestressing in preflexion process increase construction cost.

Slightly less steel is required than traditional Preflex methods, but additional processes offset cost savings.

Steel per unit

19.3 tons/unit

Direct cost per unit

KRW 74.68 million/unit

Beam cost per m²

KRW 878,000/m²

Superstructure cost per m²

KRW 180,000/m²

Total direct cost

KRW 1,058,000/m²

High steel consumption and separate 7-day curing for compressive prestressing in preflexion process raise construction cost.

(Monthly production: 8–12 units)

Steel per unit

-

Direct cost per unit

KRW 33.08 million/unit

Beam cost per m²

KRW 389,000/m²

Superstructure cost per m²

KRW 180,000/m²

Total direct cost

KRW 569,000/m²

Standard

L = 35m, B = 24.3m, 10 girder rows

Design Load: DB-24