subNav_3Tier

Bridge MULTICOM Girder Comparison with Similar Methods

(Based on 2014 Road Bridge Standards)

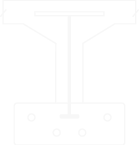

Category

Multicom Girder

Preflex Girder

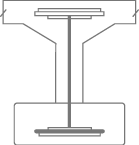

Girder Cross Section

1. Concrete block production / Steel girder fabrication

2. First tensioning

3. I/G Setting

4. Non-shrink grouting

5. Second tensioning / Grouting

6. Girder erection

7. Deck concrete pouring

1. Steel girder fabrication

2. Placing on production bed

3. Pre-flexion loading

4. Reinforcement & pouring

5. Steam curing

6. Release

7. Turn over

8. Girder erection

9. Deck concrete pouring

Materials Used

■ Steel: SM490–520

■ Concrete:

- Slab, top: 27MPa

- Lower casing: 45MPa

■ PC Strand:

- SWPC 7B 15.2, Fpy = 190MPa

■ Steel: SM490–520

■ Concrete:

- Slab, top: 27MPa

- Lower casing: 40MPa

Method Overview

A composite method that combines a pre-compressed concrete panel with an I-girder. It introduces prestress in phases to compensate for long-term loss, ensuring full composite action by correcting the camber difference between the girder and panel.

Prestress is applied to the I-girder through pre-flexion loading, then concrete is cast and released, introducing compressive prestress into the lower flange concrete to create a composite girder.

Advantages & Disadvantages

- Full prestressing prevents tensile cracks in lower casing concrete

- No need for production bed installation, fast construction, and environmentally friendly (no waste)

- Partial prestressing may cause cracks in lower casing, increasing maintenance cost

- Long-term storage after compression can lead to significant prestress loss

Cost-Effectiveness

(35M)

Uses less steel (main cost driver), and the simplified process allows mass production in a short time, making it cost-effective despite being a composite structure.

(Monthly production: 20–25 units)

Steel per unit

11.7 tons/unit

Direct cost per unit

KRW 54.6 million/unit

Requires more steel during the preflexion process. Additional 7-day curing process for compressive prestressing raises overall cost.

(Monthly production: 8–12 units)

Steel per unit

21.4 tons/unit

Direct cost per unit

KRW 90 million/unit